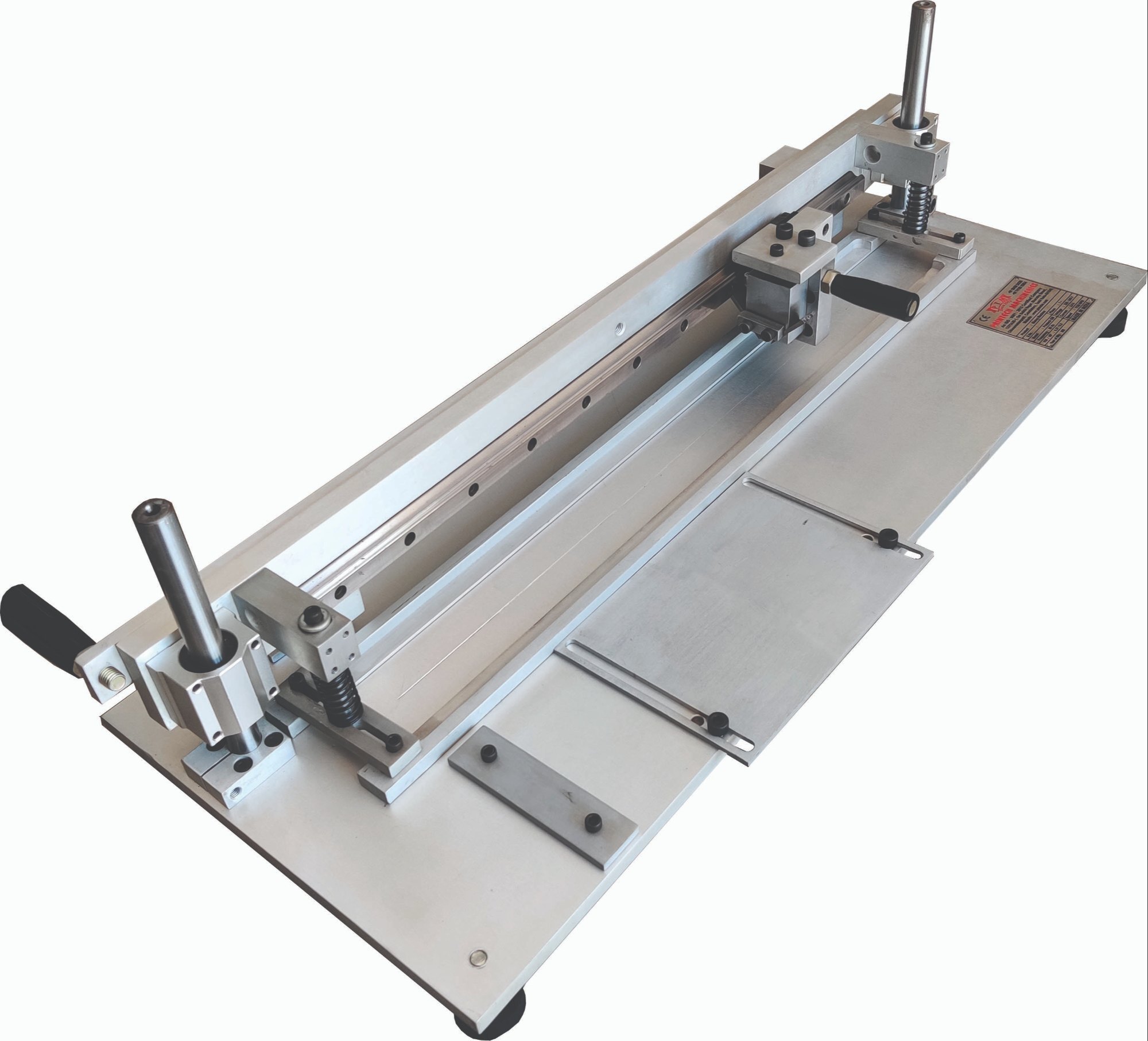

Rigid Box Making Machine

Rigid Box Making Machine Specification

- Grade

- Industrial

- Type

- Rigid Box Making Machine

- Material

- Mainly Paper Carton Board

- Capacity

- 50-60 Boxes/Minute

- Computerized

- Yes

- Control System

- PLC

- Cutting Speed

- 50-60 cycles/min

- Cutting Size

- 720 x 480 mm

- Voltage

- 220 V / 50 Hz

- Power

- 4 KW

- Weight (kg)

- 450 kg

- Dimension (L*W*H)

- 1600 x 1000 x 1800 mm

- Color

- Blue

- Warranty

- 1 Year

About Rigid Box Making Machine

- Semi-Automatic and simple to use

- Minimal power usage

- Oval cutting, corner round, etc.

|

Minimum Order Quantity |

1 Piece |

|

Capacity |

1 Ton |

|

Usage/Application |

Cutting |

|

Material |

Mild Steel |

|

Power Source |

1 HP |

|

Sheet Thickness |

upto 2 mm |

|

Cutting Material |

Iron |

|

Voltage |

230 |

|

Operation Mode |

Semi-Automatic |

|

Strokes Per Min |

10.0 |

|

Power Consumption |

1 HP |

|

Brand |

PRINTECH |

Superior Precision and Speed

Achieve high-quality rigid box production with a computerized PLC control system that ensures accurate and consistent cuts. Operating at speeds of up to 60 cycles per minute, this machine handles large-scale manufacturing with ease, increasing output while maintaining exceptional standards.

User-Friendly Operation and Durable Build

Engineered for industrial environments, the machine features straightforward PLC controls and a solid structure weighing 450 kg. Its compact design (1600 x 1000 x 1800 mm) allows integration into various factory settings and guarantees efficient, long-term performance.

Versatile Applications and Timely Support

Ideal for exporters, manufacturers, and retailers specializing in packaging, this machine processes paper carton boards into high-strength rigid boxes. Enjoy peace of mind with a 1-year warranty and dedicated supplier support throughout India.

FAQs of Rigid Box Making Machine:

Q: How does the PLC control system improve the box-making process?

A: The integrated PLC (Programmable Logic Controller) system automates key steps, enhancing accuracy and allowing operators to manage cutting size, speed, and cycle consistency. This results in higher productivity and reduced error rates during rigid box production.Q: What materials can be processed with this rigid box making machine?

A: This machine is engineered to process mainly paper carton board materials, ensuring sturdy and precise rigid boxes suitable for various packaging needs.Q: When should routine maintenance be carried out on the machine?

A: Routine maintenance is recommended every month to ensure optimal performance and longevity. More frequent checks may be necessary depending on usage intensity and workflow demands.Q: Where is the ideal location for installing this machine?

A: The machines compact dimensions make it suitable for most industrial or packaging facilities. It should be placed on a level surface in a clean, dry area with sufficient ventilation and access to a 220V/50Hz power outlet.Q: What is the step-by-step process for making rigid boxes with this equipment?

A: Feed the paper carton board into the designated intake. Use the PLC control panel to set the desired cutting size and operational speed. The machine will automatically cut, crease, and form the box, producing 50-60 boxes per minute with high consistency.Q: What are the primary benefits of using this rigid box making machine?

A: Key benefits include efficient high-speed production, precise computerized control, adaptability to various industrial settings, and robust construction for long-term use. The 1-year warranty adds extra assurance for businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gluing Machine Category

Board To Board Pasting Machine

Price Range 100000.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Metal

Color : Blue & Silver

Type : Other, Board to Board Pasting Machine

Calendar Pasting Machine

Price 110000 INR

Minimum Order Quantity : 1 Number

Material : Placeholder

Color : Placeholder

Type : Other, Calendar Pasting Machine

Hot Melt Top Gumming Automatic Machine

Price 230000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : White & Blue

Type : Other, Hot Melt Top Gumming

Sheet Gumming Machine

Price 115000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : White & Blue

Type : Other, Sheet Gumming Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS