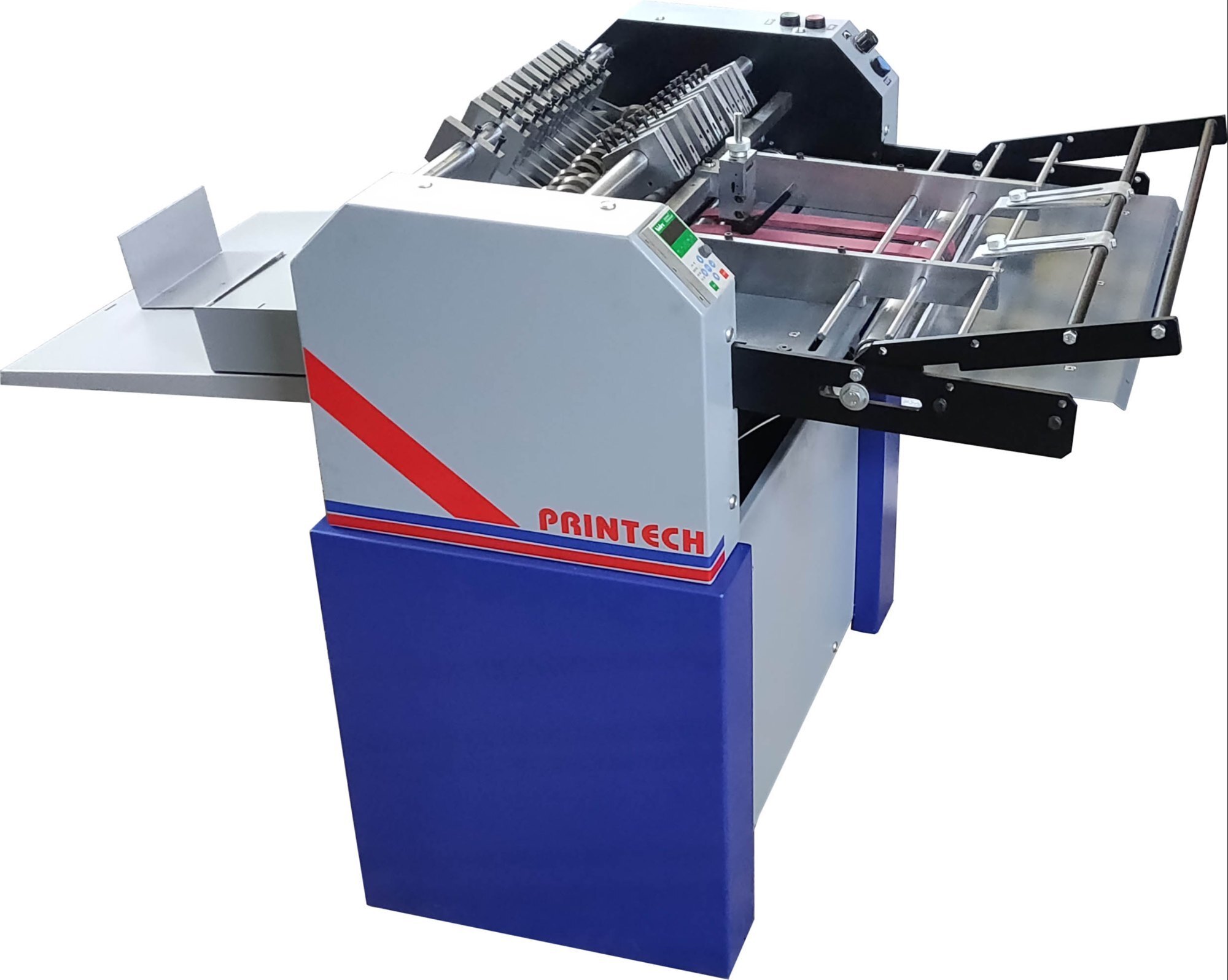

Auto Feeder Creasing Machine

Auto Feeder Creasing Machine Specification

- Grade

- Industrial

- Type

- Auto Feeder Creasing Machine

- Material

- Mild Steel

- Capacity

- Continuous

- Computerized

- Yes

- Control System

- Automatic

- Cutting Speed

- 8000 sheets/hour

- Cutting Size

- Max 650 mm x 330 mm

- Cutting Thickness

- Up to 400 gsm

- Voltage

- 220-240V, 50/60Hz

- Power

- 1.5 kW

- Weight (kg)

- Approx 320 kg

- Dimension (L*W*H)

- 1480 mm x 680 mm x 1150 mm

- Color

- Grey/Blue

- Creasing Line Quantity

- Multi-line creasing capability

- Operation Mode

- Continuous/Batch

- Noise Level

- 70 dB

- Creasing Accuracy

- 0.2 mm

- Packaging Weight

- 350 kg (with pallet)

- Feeding Mode

- Automatic Suction Feeder

- Suitable Materials

- Cardboard, Art Paper, Laminated Sheets

- Safety Features

- Emergency Stop, Protective Covers

- Display

- Digital Touch Screen

- Application

- Book Covers, Invitations, Brochures, Folders

About Auto Feeder Creasing Machine

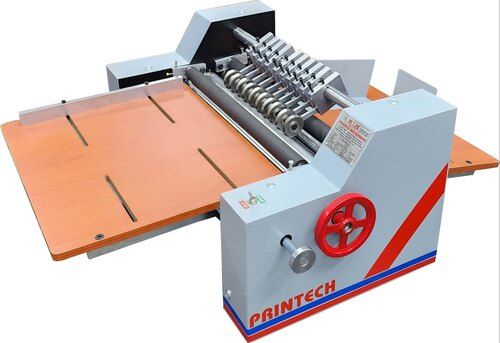

TECHNICAL SPECIFICATIONS

| Machine Sizes | 23'' X 23'' | 27'' X 27'' | 30'' X 30'' |

| Diemension | L54'' X W36'' X H42'' | L54'' X W40'' X H42'' | L54'' X W43'' X H42'' |

| No.of.Cutter | 10Nos | 10Nos | 10Nos |

| 4Line Creasing | 4Nos | 4Nos | 4Nos |

| Minimum Gap | 16mm | 16mm | 16mm |

| Minimum GSM | 45 GSM | 45 GSM | 45 GSM |

| Maximum GSM | 400 GSM | 400 GSM | 400 GSM |

| Nett Weight | 250Kgs | 280 kgs | 300Kgs |

| Power | 0.5 Hp / 1 phase | 0.5 Hp / 1 phase | 0.5 Hp / 1 phase |

| Speed | Variable Speed | Variable Speed | Variable Speed |

Salient Features:

Simple Operating Training gives Mass productionDesigned to Portable and Compact

Suitable for Micro perforation, Creasing & Sticker half cutting

Additional Spine Creasing by Male & Female in Min 3 mins.

Friction Feeding for all kind of Papers & Boards in any GSM can be adjusted according to stock thickness.

Rotary cutter can be adjusted individual and precisely.

Provided Micro Adjustment side Lay.

Max Paper Size 18 x 23 & Min 4 x 4 inches

Low Power Consumption

Efficient Automated Creasing

Featuring an automatic suction feeder, this machine significantly enhances productivity by delivering consistent and continuous creasing without manual intervention. Its rapid operation, handling up to 8000 sheets per hour, makes it perfect for bulk processing environments such as commercial print shops or packaging units. Multi-line creasing enables versatile finishing for diverse product requirements.

Unmatched Accuracy with User-Friendly Controls

Achieve precise results, thanks to the 0.2 mm creasing accuracy and clear digital touch screen interface. Operators can easily set parameters, monitor performance, and switch between continuous and batch modes. These features guarantee both easy operation and high-quality output, streamlining the finishing process for various printed materials.

Safety, Durability, and Versatility Combined

Built with industrial-grade mild steel and equipped with essential safety features like emergency stop buttons and protective covers, this machine ensures dependable operation. It supports a variety of materials and applications, serving as an essential solution for book covers, packaging, invitations, and more. Its robust construction and computerized controls make it a valuable investment for exporters, manufacturers, and commercial facilities.

FAQs of Auto Feeder Creasing Machine:

Q: How does the automatic suction feeder work in this creasing machine?

A: The automatic suction feeder is engineered to pick up sheets consistently and feed them into the creasing area without manual handling. This ensures high efficiency, reduces labor efforts, and allows for continuous or batch processing for various materials like cardboard and laminated sheets.Q: What are the main benefits of using a digital touch screen for control?

A: The digital touch screen provides an intuitive interface to set creasing parameters, monitor running status, and choose between continuous or batch operation. This helps minimize setup time, reduces operator errors, and streamlines workflow for higher productivity.Q: When should I use batch mode versus continuous mode?

A: Batch mode is ideal for handling smaller production runs or when you need to process different types of jobs separately. Continuous mode is suited for large-volume operations, enabling the machine to run uninterrupted for extended periods, maximizing efficiency.Q: What materials and thicknesses are suitable for this creasing machine?

A: This creasing machine supports materials such as cardboard, art paper, and laminated sheets up to 400 gsm and accommodates sizes up to 650 mm x 330 mm. Its perfect for products like book covers, brochures, folders, and packaging.Q: Where is the best place to install and operate this machine?

A: Given its weight (approximately 320 kg) and industrial size, the machine should be installed in a well-ventilated, flat industrial workspace with access to a suitable power supply (220-240V, 50/60Hz) and ample room for loading and unloading materials.Q: How does the machine ensure operator safety during use?

A: Equipped with emergency stop buttons and protective covers, the machine prioritizes operator safety by allowing immediate shutdown and by shielding moving parts, minimizing risks during operation.Q: What are the key advantages for exporters, manufacturers, and suppliers in India?

A: This robust, industrial-grade machine offers high-speed, accurate creasing that fulfills large-scale commercial requirements. Its durable mild steel construction, automated and computerized features, and versatile application make it a reliable asset for businesses seeking quality and operational efficiency in India and beyond.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Perforation Machine Category

Low Budget Perforation Machine

Price Range 55000.00 - 85000.00 INR / Unit

Minimum Order Quantity : 1 Number

Voltage : 220V, 50Hz

Material : Mild Steel Body

Color : Blue & Silver

Type : Other, Manual/ SemiAutomatic

Auto Feed Micro Perforation Machine

Price Range 150000.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Number

Voltage : 220V/380V

Material : Mild Steel and Stainless Steel

Color : Industrial Blue & Silver

Type : Other, Automatic Micro Perforation Machine

Double Unit Micro Perforating Machine

Price Range 1100000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 Volt (v)

Material : Stainless Steel

Color : Blue and Grey

Type : Paper Cutting Machine

Manual Feeder Micro Perforation Machine

Minimum Order Quantity : 1 Piece

Voltage : 220240 Volt (v)

Material : Stainless Steel

Color : Blue and Grey

Type : Paper Cutting Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS