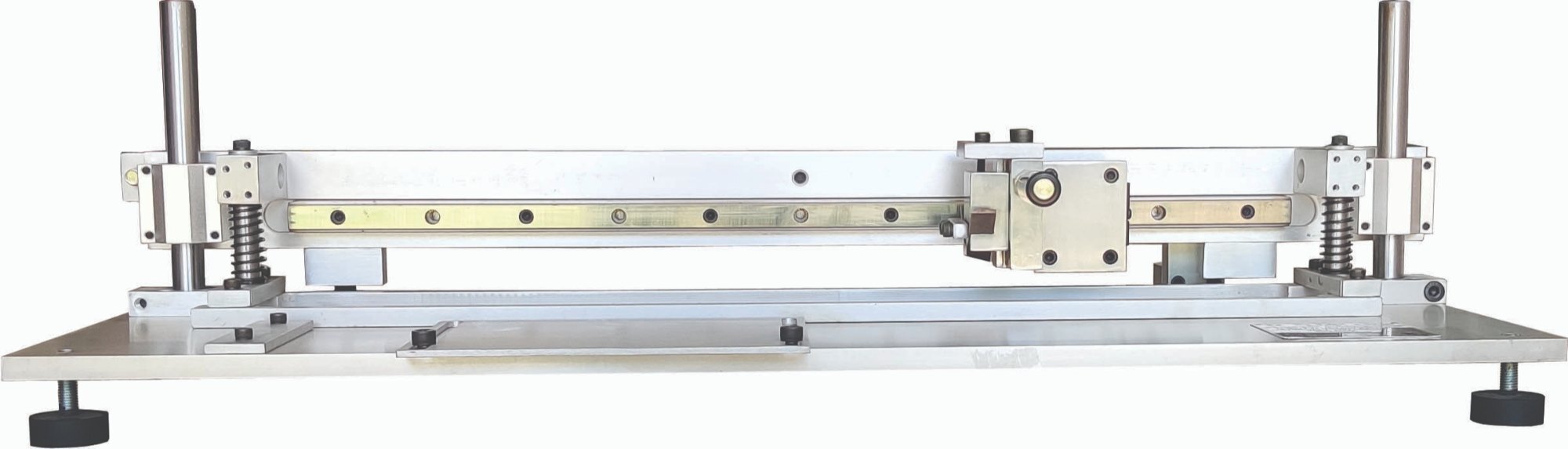

V Grooving machine Manual

Price 1 INR/ Number

V Grooving machine Manual Specification

- Grade

- Industrial

- Type

- Manual

- Material

- Stainless Steel, Mild Steel

- Capacity

- High

- Computerized

- No

- Control System

- Manual Controls

- Cutting Speed

- 8-12 m/min

- Cutting Size

- 1250 x 4000 mm

- Cutting Thickness

- 0.5 mm - 6 mm

- Voltage

- 380V / 415V

- Power

- 7.5 kW

- Weight (kg)

- 1500 kg

- Dimension (L*W*H)

- 4800 x 1800 x 1300 mm

- Color

- Blue-Grey

- Noise Level

- 75 dB

- Blade Type

- Carbide

- Grooving Angle Range

- 0 to 135 adjustable

- Cooling System

- Integrated water cooling

- Application

- Panel Grooving for Decorative Profiles

- Surface Finish

- Smooth, burr-free

- Safety Feature

- Emergency Stop Switch

- Groove Depth

- Max. 5 mm

- Operation Method

- Handwheel/Manual Feed

- Number of Blades

- 4

V Grooving machine Manual Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 15 Per Month

- Delivery Time

- 1 Week

About V Grooving machine Manual

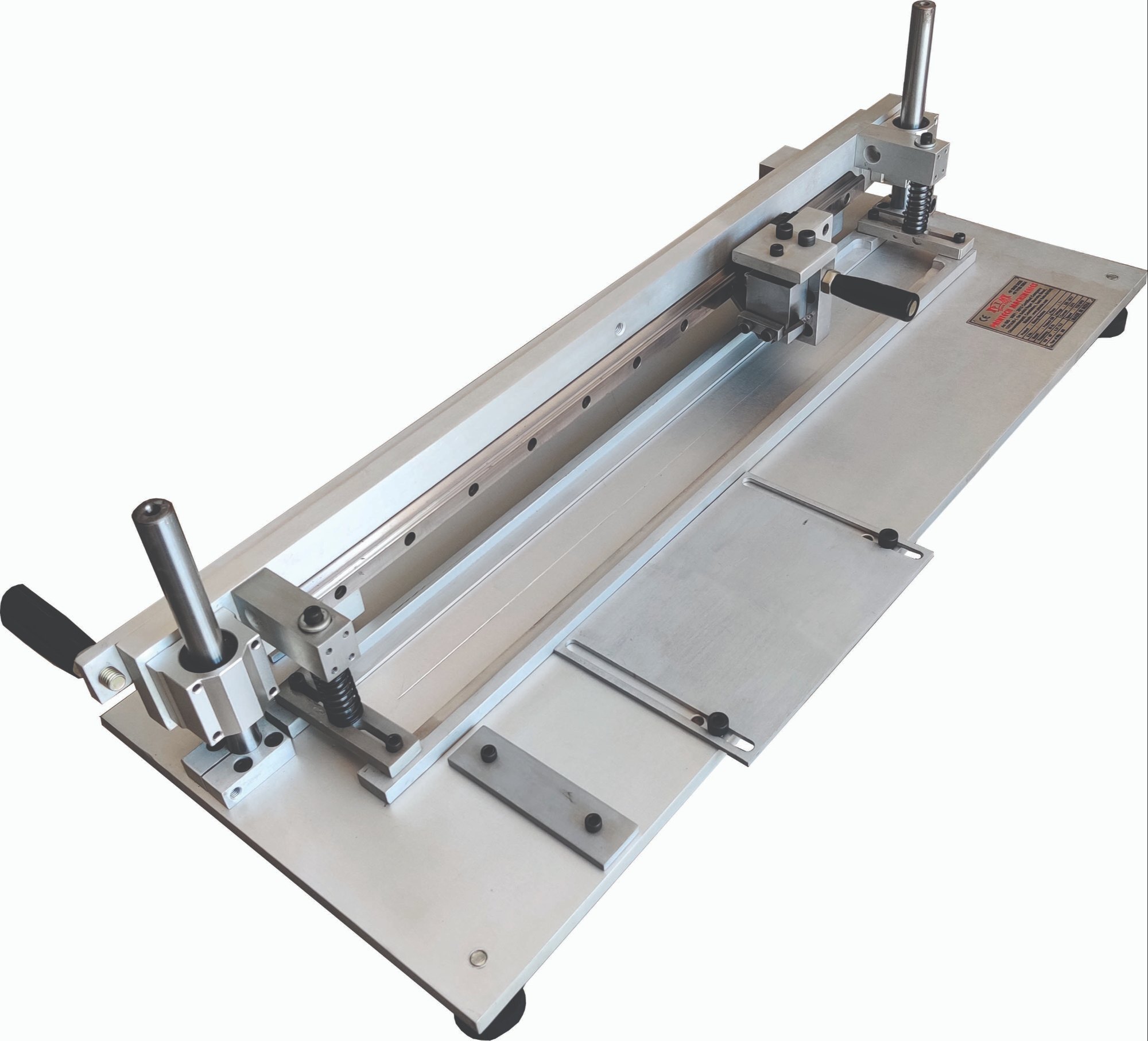

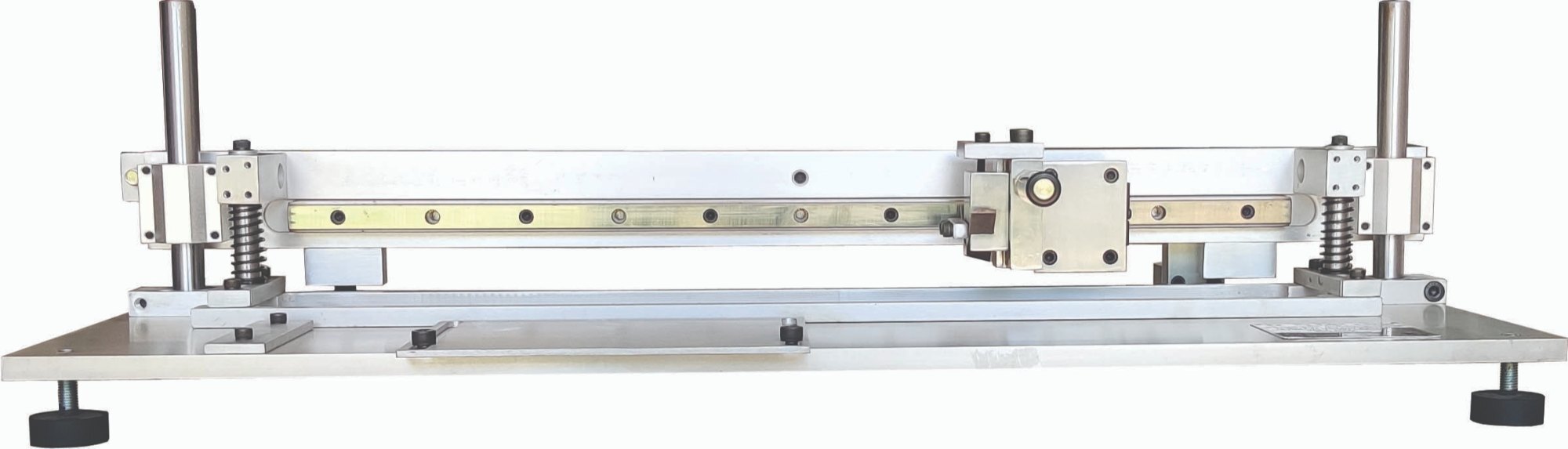

V-grooving machine by hand.

- Best-quality, heavy-duty machine

- There are a number of sizes that are adjustable.

- Manual feeding

|

Minimum Order Quantity |

1 Piece |

|

Machine Type |

Die Cutting Machines |

|

Brand |

PRINTECH |

|

Power Consumption |

NIL |

|

Usage/Application |

BOX MAKING |

|

Material |

Aluminium |

|

Voltage |

NIL |

|

Weight |

50 KG |

|

Production Capacity |

MANUAL |

|

Automation Grade |

Manual |

|

Model Name/Number |

PTMVG-25 |

|

I Deal In |

New Only |

|

Drawing Facility |

Yes |

|

AC Conveyorised Gear Motor |

No |

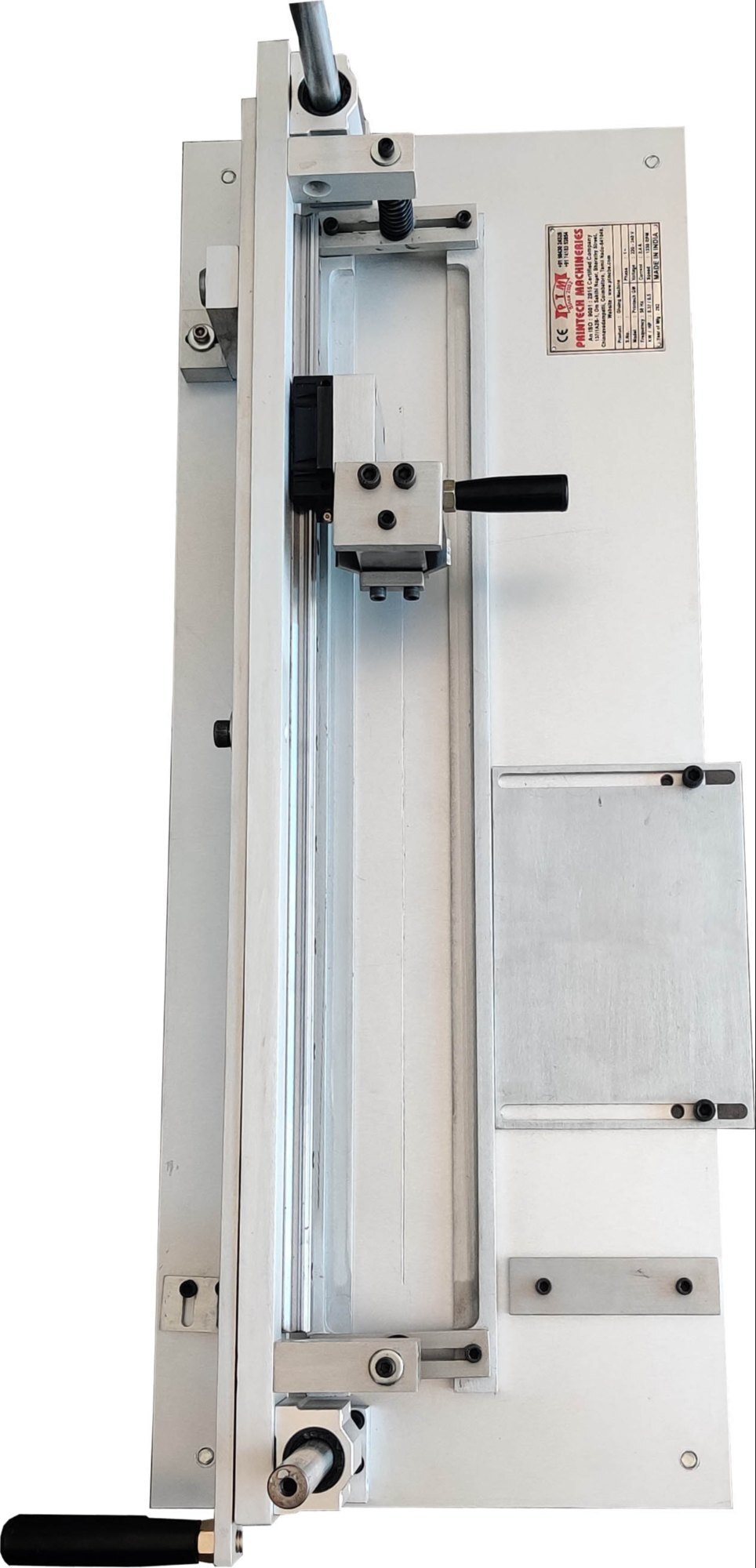

Precision Grooving for Decorative Panels

Achieve seamless grooving results for furniture and architectural profiles with the adjustable angle range, ensuring flexibility for diverse designs. The reliable handwheel operation enables controlled, manual feed, while carbide blades assure durability and quality finishes. Experience professional performance whether you are a manufacturer, supplier, or retailer in India.

Optimized Cooling and Low Noise Operation

The integrated water cooling system maintains blade efficiency and protects materials during operation, resulting in less downtime and enhanced blade life. Coupled with a noise level below 75 dB, this machine delivers a comfortable working environment, making it ideal for workshops and production facilities.

FAQs of V Grooving machine Manual:

Q: How do I adjust the grooving angle on the V Grooving Machine Manual?

A: You can set the grooving angle between 0 and 135 using the machines built-in adjustment mechanism, allowing you to customize groove profiles based on your specific decorative panel requirements.Q: What is the process for replacing the carbide blades?

A: To replace the carbide blades, turn off the machine and use standard tools to safely remove and install new blades. Always ensure the blades are securely fastened and use the emergency stop switch for added safety during maintenance.Q: When is the integrated water cooling system activated during operation?

A: The integrated water cooling system works continuously while the machine is in use, ensuring blades remain at optimum temperature and helping prevent material heat damage throughout the grooving process.Q: Where is this manual v grooving machine commonly used?

A: This machine is widely utilized by manufacturers, exporters, retailers, and suppliers in India for working on various panel materials to produce decorative profiles in furniture and interior designs.Q: What are the benefits of manual handwheel feed compared to automatic mechanisms?

A: Manual handwheel feed provides hands-on control, allowing the operator to adjust speed and pressure for greater precision. It is especially beneficial for delicate decorative groove work where finesse and accuracy are needed.Q: How does the V Grooving Machine ensure a smooth and burr-free surface finish?

A: Equipped with four high-quality carbide blades and a water cooling system, the machine minimizes friction and material tear, producing grooves that are consistently smooth and free of burrs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gluing Machine Category

Board To Board Pasting Machine

Price Range 100000.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Number

Computerized : Yes

Material : Metal

Type : Other, Board to Board Pasting Machine

Hotmelt Gumming Machine

Price Range 100000.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Number

Computerized : No

Material : Metal

Type : Hotmelt Gumming Machine, Other

Full Gumming machine

Price Range 100000.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Number

Computerized : Yes

Material : Mild Steel

Type : Other, Automatic Full Gumming Machine

Rigid Box Gumming Machine

Price 350000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Mild Steel

Type : Other, Rigid Box Gumming Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS